Guangzhou Sinon Combustion Technology Co., Ltd. is a private enterprise that acts as an intermediary, connecting industries such as steel, nonferrous metals, ceramics, and metal manufacturing. It is also a professional company that excels due to its scientific research level, technical strength, product performance, and after-sales service.

Since its establishment more than 20 years ago, our company has consistently adapted to the evolving requirements of the times and product development, ensuring continuous innovation. Our past achievements motivate us to keep moving forward without complacency, while the demands for energy saving, environmental protection, efficiency, safety, and service compel us to continuously improve and set higher standards for ourselves. As a result, Guangzhou Sinon stands out in the industry and consistently leads among its peers.

At Sinon, the laboratory has existed since the company's inception and continues to operate today. Its scale will continue to expand, and investment in it will gradually increase. Since the establishment of the laboratory, its main functions have included: testing the performance of new products to verify their feasibility; upgrading and transforming old products and comparing their performance before and after transformation to verify the feasibility of upgrades and transformations; and conducting sampling and furnace testing on each batch of products before shipping to ensure product quality.

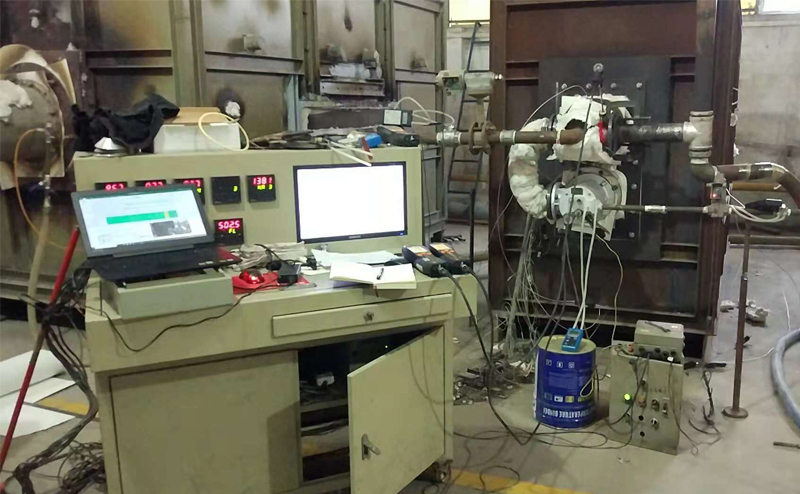

Fig.1 A SINNOx burner being tested in the laboratory

As shown in Figure 1, the laboratory is conducting an experiment on a SINNOx low NOx self-preheating radiant tube burner, which is independently developed by our company. The experiment utilizes a temperature acquisition card, integrated instrument, and multi-function controller to complete the data measurement.

Fig.2 The gas mixing station in the laboratory

Fig.3 Drying and baking ovens in the laboratory

The laboratory houses five experimental furnaces and a complete gas station to ensure gas safety and standardize experimental conditions. Additionally, the laboratory is equipped with a baking oven and a drying oven for secondary heat treatment of castable or cast burner components. These facilities form a complete laboratory system.